Company visits in Rotterdam

GKN Fokker Aerostructures:

GKN Fokker was the first company we visited on 01.03.2023. GKN is a company that many people in Kongsberg know as there is a department at the technology park.

The day started with us meeting at the Hogeschool in the museum park at 08.00, from there we took a taxi to GKN Fokker in Papendrecht. The building had a large and beautiful entrance with interactive information models. For example, they had a large screen where you could see information films that you could choose to watch. There were also a number of models with information on them. After a little while, we were moved to a meeting room where they told us about the company they work for, what they did and the history of the company.

After the meeting room we were shown around the area, the area had several buildings where one building was an office building, they had several warehouse buildings where they stored aircraft parts for production and aircraft parts for shipment, and a couple of workshops where they produced aircraft bodies.

For me, this is an exciting company to visit as it matches the education I am taking. After the tour, they told me that they need more workers and are looking to recruit, even though we were Norwegians, we had been assessed and were encouraged to apply for a job for those who wanted it.

A little about GKN Fokker The company we visited at the Papendrecht site is specialized in the production of wing components and fuselages for commercial aircraft and business jets. the site was acquired in 2015 with the Fokker acquisition of GKN Aerospace. GKN has major customers such as Airbus, Boeing, Gulfstream and Dassault. They also said that GKN has parts in approximately 90% of all operational aircraft worldwide which is quite impressive and makes GKN a strong company in this market.

Valk Welding:

On Wednesday 08.03.2023 we were going to visit Valk Welding in Alblasserdam. We met at the same school in the museum park and took a taxi from there at 08.00. Valk Welding is a company that supplies welding robots to various companies all over the world, and adapts these robots as needed. They then only use Panasonic's robots as they have a better and integrated system for welding than many other robot arm manufacturers, and that it is easier to deal with a manufacturer. Valk Welding develops and produces its own programs for the welding robot and the welding nozzle.

This was an incredibly cool company to visit and with enthusiastic staff who showed us around and told us about the company. The people who welcomed us worked in marketing in the company and I was pleasantly surprised by how much technical understanding they had.

Koninklijke Van Twist:

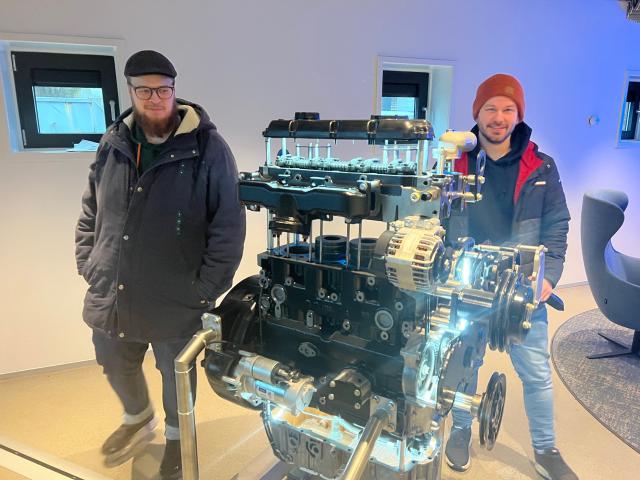

After a session of learning about the energy situation in Europe today and the challenges we are facing concerning energy and sustainability on Thursday, we met at our checkpoint on Friday at 08 am to travel with taxi to Koninklijke Van Twist.

At site we meet up with Teachers from University of applied science and with representative’s of the company. We started out tour in a meeting room where we got information of the company history.

We where introduced to and taught about how the company managed to convert regular diesel engines to hydrogen, making the engine 100% sustainable without any co2 emission.

The engins Van Twist converts are used in large backup generator systems used to secure quality and power at different companies in Europe. It was quite a surprise for us that this company addressed the exact same challenges in European power-grid that we were learning about on Thursday.

Of course, we got a tour within the company’s production hall and we also got the privilege to observe the hydrogen engine in action. This was impressive and we are after what we were told quite sure that this will be a important contribution for solving challenges with sustainability and secure our powergrid.

After the tour, we were transported back to Rotterdam and got some nice time in a beautiful environment to reflect about what we had learned.

Reflection:

The company visits on this trip were selected in a good way, in relation to the education we take, and it was also well organized in terms of the duration of the visits, little waiting and how the companies had prepared, to welcome us and show us around what they do.

These company visits made the whole trip to Rotterdam an exciting journey with new knowledge about technology and cooperation across countries.